|

Just a quick one. If after renovating you end up with some slightly broken tiles, make a matching clock out of them.

|

|

|

|

|

| # ? May 21, 2024 11:25 |

|

This is my second attempt at building an amplified portable speaker box utilizing Makita Li-Ion drill batteries. The first was quick and dirty using a small briefcase (similar to http://theboomcase.com/ ) and a couple of kit amps, which was fun and useful for a moment but the limitations were very apparent -- the enclosure was way too floppy, and there was not enough enclosure volume for the drivers. Round two -- a single 6.5" "full range" Dayton neodymium magnet (light - 2.9lbs & efficient - 94.7 dB 1W/1m) driver from Parts Express bought on black Friday, a 2x100w (@ 30V) amp also from PE, and a Belkin Bluetooth RX. Looking for light and stiff, I built up a plywood-foam-plywood laminate and taking numbers from another PE user's project with the same speaker I built an appropriately sized box. End plates and speaker rings are made of 3/4" marine ply from McMaster Carr. Once the ply arrived, and I saw the awful red-brown color I wish I had just gone with Baltic Birch, but McMaster is just SO convenient. In the name of forward progress I decided to build it anyway and paint/stain any hint of red-brown out of it. Here is is mocked up with the natural clashing woods:  End plates were tablesaw/mill and the speaker ring was made with a jigsaw and a metal lathe I was intending on doing more of a wash or stain on the wood to keep some of the grain, but it ended up being very muted. Dark grey finish is paper towel applied latex and then satin clear. The white was paper towel applied latex and then satin, but it ended up yellow, so I just shot it with Krylon white satin. Finished product:    Toggles for power, Bluetooth power, and mute. Volume control is done from the source device  2x5" Port It ended up weighing 11.2lbs with a battery. Which is pretty respectable, especially when compared to similar storebought devices (TDK 2 Speaker Boombox = 16lb + 10 D batteries) Nothing to see here! Note I still haven't committed to buying a Makita setup yet, and have been borrowing batteries from work as needed. Testing with an old 12V Dewalt nicad pack here. There is a Makita battery adaptor integrated into that lower cavity.  Oh and it's pretty loving loud. Sadly the speaker rolls off heavily down low, so pt 2 will be the accessory subwoofer that will use the amp's second channel to help fill in the bottom end. iPhone RTA screenie of a sine sweep

Blooot fucked around with this message at 18:12 on Feb 8, 2013 |

|

|

|

Blooot posted:Finished product: That's frickin' awesome! (too much Gold Rush) Seriously though, that looks sweet. Needs more video!

|

|

|

|

Blooot posted:a 2x100w (@ 30V) amp also from PE What are you doing with the 2nd channel if you've only got the one driver? Or does the amp behave without the 2nd channel loaded? Cool project.

|

|

|

|

So pretty, it almost makes me nostalgic for the annoying people who brought boomboxes to the beach in the 90s.

|

|

|

|

So, do you have to open it up if you wanted to bluetooth-pair it with another device, or does it automatically go into pairing mode on power on or what?

|

|

|

|

I just moved into a new house, it's a rental but the landlord is having me do some restoration/modernizing it on his dime. I decided to do this little project on my own, though. It started with this built in bookshelf.  A friend of mine pointed out that my TV would look awesome in there and I agreed. At first I thought it'd be as easy as just taking the shelves out, but no such luck.  As it turns out, these were built in a rather annoying order. First the shelves were nailed to the walls, then some incredibly thin drywall were put up between them. This meant 2 things. 1) There were gaps in the drywall behind the shelves, and due to how thin the drywall was there were already some cracks and gaps from the drywall warping in the decades since it was installed. 2) The shelves couldn't be removed without first removing all the drywall. At this point, I decided to just make it a full on project and build an actual wall that shelves could be reattached to later.  Most of the drywall removed.  All of the drywall removed.  Due to the fact that the inner space is smaller than the outer space I couldn't just build the frame in one piece and install it, and due to the fact that whoever built this clearly just eyeballed everything there were no reference points to measure from, so I mounted the bottom 2x4 first, used the two side 2x4's to prop up the top 2x4, leveled the side 2x4's to make sure that everything was square, and then screwed the bottom and top 2x4's in. The drywall on the sides will be screwed to the old shelf mounts.  At this point I built the rest of the frame which could be put in in one piece.  The whole frame installed  I initially planned on putting the whole back sheet of drywall in at once, but realized that wasn't possible, so I cut it in half and installed it like this.  I also installed an outlet to power the TV/everything else.  Most of the drywall installed.  Spackled  Mostly primed  Painted  Oh my god, a TV!  I found some color changing LEDs that I never had a use for and stuck them behind the TV. I think purple is the most relaxing color.  There it is! I'm really happy with it, especially for a 3 day after work project. Definitely a lot of work for something that looks almost identical to before, just without shelves, but at least now there's a real frame in the back so I can potentially mount the TV on a wall mount at some point, or just add shelves. My plan is to add a shelf on top of the TV and possibly some small shelves on the sides of the TV. That can wait though. I'm going to have a lot more projects in this house so I'll be sure to take pictures of all that too! They include: Ripping down the incredibly ugly tiles on my bathroom walls and replacing with sheetrock, and retiling the area around the bathtub with something less hideous. Replacing all the old cheap cabinets and counters in the kitchen. Taking the backyard from a bunch of cinderblocks, car tires and dirt to a nice yard with grass. And a bunch more. Next real project is opening up a doorway between the garage and the large storage room attached to the garage, and then tearing out the carpet and building some work benches. I've already replaced all the lightswitches in the house, as they'd all been painted over at least 10 times and were physically difficult to flip, as well as all the lightswitch covers and outlet covers. A hardware store by me is going out of business so I was able to get a dozen lightswitches, a couple outlets, and a whole bunch of outlet and switch covers for about $10. Edit: I realized that first picture looks ridiculously goony, but that was the second day in the house, I have couches now!  My next small project is painting the inexplicably pink fireplace. omgitstheinternet fucked around with this message at 13:44 on Feb 9, 2013 |

|

|

|

That's awesome. Looks great.

|

|

|

|

If you've got an HTPC hooked up to that TV, you should build an Adalight! http://learn.adafruit.com/adalight-diy-ambient-tv-lighting

|

|

|

|

Base Emitter posted:What are you doing with the 2nd channel if you've only got the one driver? Or does the amp behave without the 2nd channel loaded? Thanks. It seems to be fine running only one channel. With nothing hooked up, it doesn't have to do anything. My plan is to run the 2nd channel output to a second box with a low pass and a sub in it. Flipperwaldt posted:So, do you have to open it up if you wanted to bluetooth-pair it with another device, or does it automatically go into pairing mode on power on or what? I'm using an off-the-shelf Belkin unit that doesn't auto-pair, just power it up and then pair your device with it. No opening required.

|

|

|

|

Blooot posted:I'm using an off-the-shelf Belkin unit that doesn't auto-pair, just power it up and then pair your device with it. No opening required. There's definitely a case to be made for either method. Auto pairing is nice if you're always using the same source, but I see how that would have complicated your project unnecessarily. Anyway, very cool. It's been too long since I had such a project of my own'.

|

|

|

|

Zuph posted:If you've got an HTPC hooked up to that TV, you should build an Adalight! http://learn.adafruit.com/adalight-diy-ambient-tv-lighting That is incredibly cool! I don't have a computer hooked up to the TV yet but that is a plan for the near future and I will absolutely try that out when I do have one. omgitstheinternet fucked around with this message at 19:13 on Feb 11, 2013 |

|

|

|

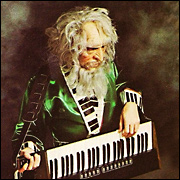

A few months ago, this thread was posted about a YOSposter getting a Raspberry Pi and not knowing what to do with it. I jokingly said: quote:if somebody sends me a raspberry pi free of charge i will build a bong that tweets when somebody hits it. Channeling the old trope that burnt-out old hippies can make a bong out of anything and all that. Well, the idea grew legs and we decided to actually use the electronics as an integral part of the device. So, we decided to build a vaporizer. A computer-controlled, internet-connected vaporizer. This was my first mockup.  A block diagram (this actually ended up matching final design almost exactly, with the change being that we drove the LCD off of the Arduino instead of the Pi, and didn't do an air flow meter)  I was ruminating one day on how to package it, when my eyes fell on the empty G4 Cube case that I had been using as a speaker stand. I had no other choice. It *had* to be done. I learned a lot of tricks and did a lot of fab along the way. Some of it worked:     Some of it didn't.  --- Months and dollars and many, many engineering challenges later, we have completed construction and all hardware works perfectly.  I have a couple software/UI bugs to sort out, but that's pretty much it. It feels like I designed a Japanese car. Everything has its place, there is no room for my hands to work, and every screw has to be driven in the right order if you want them all in - and half of them need a flex driver. We're posting to the Make/Hackaday sites on tomorrow, 2/19, and calling it 1.0. This is not the end of the project. I, do, however, need a serious break. (Unless you're really not a fan of the culture this is part of...) Check out the thread if you want a big old long epic tale about ~goon projects~, hardware hacking and one man's voyage from "joke" to "Shipped" http://raspberryhigh.wikia.com is our little wiki, I don't have it completely up to date but that will be sorted by tomorrow.

|

|

|

|

Been checking up on that thread for a long while... end product 1 lookin fly and fresh. I'm ready for web4.20.

|

|

|

|

I made a shed! Drew up some plans, consulted a handy neighbor for advice, and built it up. Making the doors out of leftover plywood was fun. Now I am waiting for it to warm up so I can paint it.

|

|

|

|

Where I want my kitchen table is not where the light fixture box is, and to make matters worse the ceiling is vaulted and there's no attic above. So I want to make a pulley pendant light to span the distance. Something like this:  My thought is to use a piece of capped black iron pipe hanging vertically as the weight and to add weight inside of it if needed. But I'm having some trouble figuring out how to attach the pipe to the pulley. My current thought is to buy something like this and remove the swivel and use a bushing to take the pipe down to the size where I could run a bolt through the hole.  Any suggestions? Or ideas for a weight besides a piece of pipe? Hashtag Banterzone fucked around with this message at 21:14 on Feb 18, 2013 |

|

|

|

Get a short bolt, a nut, and a pipe cap that threads on to the end of your pipe. Hacksaw through that hook thing near the pulley body, and throw it away. Drill a hole through the center of the pipe cap), push the bolt through it (from the inside of the cap, through the hole in the pulley frame, and stick the nut on the end inside the frame and tighten it down. Now screw the cap on the end of the pipe. Should be good. I like the pipe idea actually, it serves both as counterweight and a lift/lower handle. Just be careful you don't whack your noggin on it.

|

|

|

|

Have to agree with Jonny, thats propably the easiest way to do it. Or perhaps just some heavy duty chain and then just add and remove links when necessary. And made a simple lamp for my kitchen table

|

|

|

|

Mercury Ballistic posted:I made a shed! Drew up some plans, consulted a handy neighbor for advice, and built it up. Making the doors out of leftover plywood was fun. Now I am waiting for it to warm up so I can paint it. awesome, any chance you could post the plans and bill of materials? I need to build me a shed this year

|

|

|

|

Jonny 290 posted:

You could prototype that with Kickstarter so fast. Well, assuming potheads were motivated enough, you might just get a lot of people stuck at the checkout process.

|

|

|

|

Nebulis01 posted:awesome, any chance you could post the plans and bill of materials? I need to build me a shed this year I can scan the drawing I used if you like, but I wandered off the plan when it suited me. The dimensions inside the plywood siding were 93" wide, 45" deep and 72" tall at the front and 60" at the rear. The floor was Pressure treated 2x4s, on end at 16" intervals, with some 3/4" or so PT plywood. Walls were regular 2x4 and the siding was T-111 or whatever they call it. Two pieces for the rear, one for each side and one for the front. Then used leftovers for the doors. Rested the thing on pavers so I could move it if need be. The roof was 5/8" plywood I think, with tarpaper and shingles. All told it came to about $500. I did have some screws and odds and ends laying around at the start though. I would have made it bigger, but the size was limited by the space available. This was my first attempt at building anything, so I have no doubts there are better and/or more efficient ways to do what I did, but I like to learn by doing and it was fun either way.

|

|

|

|

Didn't know if this should go in the Bonsai or gardening thread, so here you go. I made these for a friend out eggs from my quail after she said she wanted something like it through pintrest or whatever. I think she will be happy with it  The black thing in the shell on the right is a pretty piece of obsidian but it didn't come through in the shot (because I suck at cameras).

|

|

|

|

Mercury Ballistic posted:A shed IŽd love to get the drawings too. planning my first shed this summer. you can mail it to suneholms @ gmail.com IŽd much appreciate it.

|

|

|

|

Prophaniti posted:IŽd love to get the drawings too. planning my first shed this summer. you can mail it to suneholms @ gmail.com IŽd much appreciate it. Or just host it somewhere and post a link! I'd like to see them as well.

|

|

|

|

Ok, so here are some more pics. Please be kind, my workmanship is not up to where I wish it was. The drawing is more or less correct and the additional photos should help a bit.  My sketch. Note the high school geometry. In the side view, the longest vertical 2x4s are flat side forward, which is not how they are drawn.  Left inside wall and back corner.  Left inside front wall.  Left exterior. I'm not happy with the gap at the bottom of the 1x6 trim. Since there is no drawing of the floor or roof here it what I did. The floor is pressure treated plywood and 2x4s on end. Outside dimensions of 45" x 93", resting on 6 pavers. The roof is two pieces of plywood, with about a 3" overhang on the front and about 1" on the rear. Five 2x4s are supporting it as seen in the pics. Over the plywood, is tarpaper and then some cheap home depot shingles. I was uncertain how to handle the top course of shingles so I covered it with some drip edge held in place with some galvanized screws. Not perfect, but so far no water had gotten in. The roof supports on the front are covered with a single 2x4 (visible in the 3rd picture) and then over that a 1x6 trim piece that extends all the way around the roof. I also used the 1x6 to reenforce the plywood I then made into doors. Thanks for the interest, and I hope my explanation makes some sense.

|

|

|

|

Thanks alot. Thats gonna be really helpful since I have no clue what iŽm doing

|

|

|

|

We tied a ribbon on YOSVape, it is now a Finished Project. This particular unit will not be touched again save for software upgrades or repairs. I have some future goals for the project, but for now I'm just going to relax and enjoy the thing. This is definitely not the end of the road for this, though. You can get more info and rambling by checking the wiki. http://raspberryhigh.wikia.com/wiki/Raspberryhigh_Wiki I am honored that the thread was considered Goldmine-worthy as well. http://forums.somethingawful.com/showthread.php?threadid=3507531 And a tiny vid: https://www.youtube.com/watch?v=tuGWDsq4rfc

|

|

|

|

This is more of my parents project than mine but but drat I have put some hours in on it... We are currently remodeling my grandmothers house that they are moving into, no real pics of the kitchen before but it wasnt in bad shape just needed updating, which lead to a new floor, closing a entry to a small dinning room and adding a entry to the living room, removing wall paper in all the rooms, cleaning years of cigarette smoke from every surface and updating the wiring... After all the demo we worked on the kitchen to get it finished for cabinets to be installed.      Waiting on counter top templates to be finalized and the cabinet installers have a few things to finish... Still pissed about the few marks on the fresh new drywall we busted our asses to get finished... Just the rest of the whole house to mud, sand, and paint...

|

|

|

|

I've been working on some "free" projects around the house. First was to remove some walls for what we were using as a storage room. Storage is important, but a pool table is going to be more important. Before  No more wall (don't worry there is a steel beam being used as a support close to where the drop ceiling ends)  So now I have all those bins and poo poo. Phase two was to clean up our furnace room and build shelves for the bins to go on to make them much more easy to get at. Before (not my dog)  Shelves!  I did have to buy some lumber and plywood but a lot of the lumber was sourced from those walls I took down. I have a lot of cleaning and organizing to do but it's a good start. Down the road I may build another 8' section of shelves where I was standing in the picture.

|

|

|

|

Down with the wall paper and plaster and up with new drywall. Put a door way where there was a wall.  And put a wall where there was a door.  Lots of sanding in priming left to do but we should get some color on the walls soon.

|

|

|

|

Blooot posted:Finished product: That's really sexy Blooot.

|

|

|

|

So about 6 weeks ago I decided to rip out my old master shower (2005 Pulte Homes built suburban hellscape house, standard plastic shower/tray). Second floor of house. I have another shower and am taking my time so I don't gently caress anything up and have leaks. I was trying to keep the overall budget (including fixtures) at around $2500. I am gonna go over that most likely since I'll need a new shower door frame and hopefully the installer can re-use the existing glass that came with the shower. Bought a Kerdi shower kit/pan.  Tore the old poo poo out.   I had previously done some tile around the tub but since I was changing the rest, I am re-doing it. I had to replace all the drywall which was beat to poo poo around the tub and had to be cut out around the shower to remove the pan anyway. Also gave me a chance to caulk, spray foam and add more insulation to the outer wall, shower-tub wall (which had none and was cold as hell in the winter - even in California.)  Nice thinset guys, very stable. That explains why the pos was creaking all the time.  Here is the cutout to reach the tub fixtures. Added more insulation and sprayfoam under there as it's right above the living room and also freezing in the winter. You could feel the tub just get cold quickly no matter how hot the water was. The house came with Moen M-PACT mixing valves so replacing the faucets will be easy. EDIT: I had to order new plastic extension thingies for the hot/cold levers for the faucets from Amazon because the originals were torn up.  Added R19, spray foam (cans) and started replacing drywall. The yellow insulation is what came with the house and was replaced with R19.   Finished replacing the drywall patched all the seams and screwholes my own sloppy way, then added Redgard to it. I wasn't concerned with it acting as waterproofing just wanted to seal everything up a bit more and also fill any cracks and keep the loving ants out. Pro's might say I am risking a "moisture sandwich" but it's dry as hell where I live (130 miles east of San Francisco) so most of the moisture would be coming from the shower, not outside and the redgard is under a layer of cement backerboard.  Hardibacker going up.  Yeah, it's in pieces but gently caress it I am putting Kerdi over it.  More around tub  Replaced tub drain/overflow with Watco Oil Rubbed bronze pieces. I really built out the wall here with water resistant drywall/redgard/hardibacker. It should be well insulated now.  Dry fit the pan/drain  Attach the ABS drain, and mud it all in with the Kerdi using Bostick Ditra-set from Bedrosians Tile (great place for Kerdi stuff!). Since my drain is slightly off center I had to build up one side of the pan with thinset to match the height of the other side. Added extra corner pieces from the shower kit. Also filled up the block with thinset so it will be heavy and solid. Yeah, I'm messy...whatever.  Started tiling around the tub with 2x4 travertine. I have used a bunch of this in my house for kitchen backsplashes, fireplace surrounds and its very easy to work with. The shower will be done with 16" travertine that I will cut in half and place like giant subway tiles.   My loving back hurts and I need to take a hot bath so gently caress it I'm putting the fixtures on now and turning the water back on! My goal is to be done in another 2 or 3 weeks working on weekends. It's gonna take a while to cut and clean up all the 16" tiles anyway..... Keyser_Soze fucked around with this message at 22:33 on Mar 6, 2013 |

|

|

|

The house renovation construction projects are loving great. I don't know how you guys do it. A cross post from the woodworking thread, but I figured it goes better in this thread. Not a renovation, but a single malt scotch cabinet that I'm just about finished with. I've been doing woodworking for about 10 years, pretty much all power tools. About 2 years ago I had a bad day and a plunge router I was working with came "un-plunged" while in a jig and decided to come flying out of the jig and at me. Trying to get out of the way of a spinning router that is falling from a bench is not fun, and I'm lucky I didn't hurt myself. At that point I seriously considered why I was using these tools for a so-called "hobby", when I constantly feared for my own demise. I slowly starting switching to hand tools, bought some old saws, planes, etc and haven't turned back. I still use my band saw for rip cuts and my lathe occasionally, and I've made a few emergency crosscuts on my table saw, but it's been mostly hand tools lately. I love the quiet it brings, the lack of fine sawdust and feeling of being slightly in control of the tool. Anyway, I love single malts and have been hogging the bar in our house, so I decided to make a big hanging cabinet. The carcase is mahogany, the small shelves are tiger maple, the back is walnut, the lower door panel is laurel burl veneered panels and the upper panel is amber mica. The case construction is dovetails, the main shelf is a wedged through-mortise. The doors are all M&T construction. So far it has an oil base coat and 3 coats of Arm-R-Seal top coat. It's 32" tall by 42" wide. I'm hoping to have it up by Sunday or Monday, if all goes well. Some progress photos - Dovetail dry fit  Rabbet plane, quite old, doing it's job (gently caress you router, I don't need you anymore)

|

|

|

|

Crosspost from the woodworking thread... Here's the speakers I built for my girlfriend's birthday. The sides are oak and I hand cut dovetails for the joinery. The front and back are MDF, I used a router to countersink the drivers and bevel the edge of the faceplate. The back sits flush with the box, I put some pine bracing in the back with weatherstripping to flush mount it and seal it. I bought the drivers and internals from a local supplier, they were pretty cheap but sound pretty good, I want to change out the crossover because I just used some crappy calculator online and didn't spend the time to do it properly so they sound pretty bright, need to balance the sensitivity of the tweeter with the woofer.  I had to spend a bit of time to clean the dovetails up on the first box, on the second I was starting to get the hang of them  I still need to put a few more coats of clear on the MDF and spend some time sanding and buffing, I want to go for a mirror finish. Also need a few coats of poly on the sides, but I needed them for a party so here they are.  Close up of the dovetails.

|

|

|

|

Sometimes it's fun to go way back to the most fundamental basics of a hobby. I had a friend visit with some kids (4 and 6 years old) and they were asking to do something in my shop, so I helped them make birdhouses...then, I got all jealous that they got to go home with these awesome little birdhouses, so I made some of my own. About $3 in materials per house, I'm all right with that. Assembled, ready for painting  First coat down  I'll put on a couple more coats tomorrow and they'll be done, ready for someone to move in.

|

|

|

|

|

Keyser S0ze posted:shower redo Thanks for this! I'm actually redoing a shower in my house right now and I'm trying to absorb any sort of information I can find on it.

|

|

|

|

Bad Munki posted:Sometimes it's fun to go way back to the most fundamental basics of a hobby. I had a friend visit with some kids (4 and 6 years old) and they were asking to do something in my shop, so I helped them make birdhouses...then, I got all jealous that they got to go home with these awesome little birdhouses, so I made some of my own. About $3 in materials per house, I'm all right with that. I know the feeling, I'm having my niece in town for Easter so I decided to build her an Easter basket. Sometimes the glues and screws projects are great fun and a great diversion.

|

|

|

|

Finally finished laying most of the tile a few days ago and got some grouting done today. Still have the pan left to tile/grout. Then I'll give a few weeks to all cure before I run a water test and then put some nice glossy sealer on it and call the shower door guy. I chose grout that will dry very close to the tile color to help hide any goofy poo poo I did. Still have to do more bullnosing/polishing wetsanding with 800 grit on the edges and should be done next weekend.    My other guest shower I will use the same tile but it will be way easier since the tub will stay. I would suggest anyone using Kerdi to either spray the hardibacker with water as you are placing it or use modified thinset under the Kerdi and the unmodified Bostik stuff over it. The hardibacker sucks all the moisture out of the thinset and I had to re-do a few spots with patches that had pulled up. April 4 Update: As it looks now, still have bullnosing and polishing of the edges left and need to call a shower door installer to replace the existing frame. Ran plenty of water tests and everything is draining well and no leaks below. I'll let everything cure for a few more weeks before I throw on some sealant.

Keyser_Soze fucked around with this message at 01:24 on Apr 5, 2013 |

|

|

|

Put in some wood-laminate flooring in my den a few weekends ago. Forgot to take full "before" pics, but the whole room was covered in this "old-lady-green" carpet: Now it looks like this:     I still need to do the transition pieces around the fireplace and where it meets the dining areal. But I'm super happy with how it turned out. Up next I'm thinking about stripping the paint off the fireplace/mantle and staining it. It's got a nice grain underneath.

|

|

|

|

|

| # ? May 21, 2024 11:25 |

|

2 Things for today. First up is a lathe tool tray made from ABS pipe and plywood. It has a cleat in the back that fits into the lathe bed and holds it still.  Second up is the marking knife I made for a tool swap on another forum. I had a little last minute issue, apparently lacquer dissolves the red color in padauk. Despite that, I really liked the knife and the fatter shape is/was more comfortable to me than most knifes. Woods are walnut, spalted maple and padauk; blade made from a Dewalt saw blade. If you look on the right end of the handle you can see a break in the walnut. The piece of walnut I used had a birch dowel running through it and I thought I had cut it out but when I turned the handle down it suddenly appeared.  Marking knives are specially made knives for marking wood, the fine line allows more precision than a pencil.

|

|

|