|

Is that a Myford? Looks a lot like the lathe I had at my old job. A Myford ML7

|

|

|

|

|

| # ? May 24, 2024 01:50 |

|

cakesmith handyman posted:Holy poo poo Ambrose. $2.50? yep. i got my smith-corona for $2.50 at a different estate auction too, looked up sale prices for em in good restored condition and it's something like ~$400-600 CAD for my model. $2.50 just happens to be a common lowest-possible-bid for those things and nobody else cared enough to pitch for $5. friggin estate sales man, the deals are extremely real

|

|

|

|

Brekelefuw posted:Is that a Myford? No this is a swedish lathe, Rexvalter VF-118: http://www.lathes.co.uk/rexvalter/

|

|

|

|

That lathe is like the perfect size and complexity for a home gamer. Well done.

|

|

|

|

This might be a bit of a long shot but this is the best thread to ask this in. I remember seeing a youtube video showing the forging process of various Apollo rocket parts especially the nose cone out of exotic metals like niobium. It was some vintage film that was mostly highlighting the giant forging presses involved. I got into a conversation with my metallurgy teacher about it after he mentioned the rocket nozzle materials at this firm he works at called Aerojet.

|

|

|

|

Slung Blade posted:That lathe is like the perfect size and complexity for a home gamer. Well done. Thanks on paper it looks really nice, only the future will tell how well it works, how accurate/worn it is. Don't even have a dial indicator, though one has been ordered. I also ordered a manual from the site I linked, hopefully it'll arrive soon. The lead screw and halfnuts being used for powerfeeding as well was something of a disappointment, I believe I will make it a project to be able to make new lead screws easily and accurately using delrin or acetal. Cross slide bronze nut also is worn, I wonder if delrin would be a good replacement over bronze...

|

|

|

Ziggy Smalls posted:This might be a bit of a long shot but this is the best thread to ask this in. I remember seeing a youtube video showing the forging process of various Apollo rocket parts especially the nose cone out of exotic metals like niobium. It was some vintage film that was mostly highlighting the giant forging presses involved. I got into a conversation with my metallurgy teacher about it after he mentioned the rocket nozzle materials at this firm he works at called Aerojet. The space flight thread might have someone who knows if not here

|

|

|

|

Ziggy Smalls posted:This might be a bit of a long shot but this is the best thread to ask this in. I remember seeing a youtube video showing the forging process of various Apollo rocket parts especially the nose cone out of exotic metals like niobium. It was some vintage film that was mostly highlighting the giant forging presses involved. I got into a conversation with my metallurgy teacher about it after he mentioned the rocket nozzle materials at this firm he works at called Aerojet.

|

|

|

|

|

Yooper posted:Might want to look into the Heavy Press Program. That reminded me of this awesome video; https://www.youtube.com/watch?v=CHKbAq_RtIY

|

|

|

|

MrPete posted:That reminded me of this awesome video; https://www.youtube.com/watch?v=CHKbAq_RtIY I'm so grateful I've never had to work in a foundry, goddamn.

|

|

|

|

MrPete posted:That reminded me of this awesome video; https://www.youtube.com/watch?v=CHKbAq_RtIY This is actually the exact video I was looking for! Thank you!

|

|

|

|

https://twitter.com/qikipedia/status/928170223072612352 Pretty cool concept.

|

|

|

|

Is there a good food-safe coating for copper, preferably one that preserves patina? I'm making a copper wineglass that I plan to patina with ammonia and salt. I've found a few people saying ProtectaClear is food safe, but no concrete information. I'm also not sure if the alcohol in wine would interfere with the coating.

|

|

|

Grey Face posted:Is there a good food-safe coating for copper, preferably one that preserves patina? I'm making a copper wineglass that I plan to patina with ammonia and salt. I've found a few people saying ProtectaClear is food safe, but no concrete information. I'm also not sure if the alcohol in wine would interfere with the coating. The website says it is foodsafe when cured. You could also look at a food safe epoxy. https://www.everbritecoatings.com/faq.html#gsc.tab=0

|

|

|

|

|

Are you married to a visible patina interior? If you are, yeah, i think that might be your best bet. I think there are similar curing-plastic-based linings but afaik theyíve all got pthalates, if youíre concerned about that kind of thing. You may also be able to use a heat-gun to form some LDPE plastic sheet to the interior, no idea if itíll bind well to the cup interior but they do something similar for nontoxic-minded bottle liners and the like. If you donít mind a different interior look, keep it simple and use the traditional food-safe lining of a tin wash. I lined a copper flask that way, it was tricky but your vessel would be much easier to tin. You could also silverplate the interior with electroplating, using the vessel itself as the cathode and a piece of silver as the consumable anode. Never actually tried it, though. You can even melt some beeswax and swirl it around the interior to line it, thatís how I saw a cowís horn lined for use as a drinking horn. Itíll be translucent so some of the copper look will get through if you keep the lining thin. Makes cleaning the vessel tough, though, because itís a heat-sensitive and very soft lining (easy to restore tho, which is good, just use spot heating to repair localized damage to the wax). Ambrose Burnside fucked around with this message at 21:50 on Nov 8, 2017 |

|

|

|

Wouldn't that make everything taste vaguely like honey?

|

|

|

|

because i go the extra mile for my metalworking thread pals, i have consulted my bulk block of beeswax to confirm that pure beeswax is essentially tasteless (it's insoluble in water and almost totally insoluble in pure alcohol, so as far as a weak solution of alcohol in water is concerned beeswax is basically inert, and actual sugars/honey shouldn't remain in commercially-processed wax anyways) Ambrose Burnside fucked around with this message at 20:27 on Nov 10, 2017 |

|

|

|

I don't remember when or how I discovered this but it's surprisingly easy to distinguish between stainless and galvy fasteners by flavor.

|

|

|

|

Nice fresh blocks of beeswax sure smell like delicious honey when you're coating something. Mm-mm I love that smell when the heat's just right.

|

|

|

|

shame on an IGA posted:I don't remember when or how I discovered this but it's surprisingly easy to distinguish between stainless and galvy fasteners by flavor. New thread title.

|

|

|

|

Kinda hard to beat homemade buttplug thread title imho

|

|

|

|

|

Yeah, but you gotta spice it up once every couple years.

|

|

|

|

Dumb baby question at the timestamp (4:10) in this video, he adds something tinto the hole of the head as he's working on it that then seems to burst into flames. https://www.youtube.com/watch?v=PWtwZSgJoEY&t=250s Two questions: What is it? Why add it? I have no idea on the "what" but on the "why" I'm guessing to reheat the area being worked because my understanding is that the spike he's using to work the hole is sucking a ton of heat out of the metal there. Anyone care to comment?

|

|

|

|

Magres posted:Dumb baby question at the timestamp (4:10) in this video, he adds something tinto the hole of the head as he's working on it that then seems to burst into flames. Its probaby charcoal or some coal dust to act as an anti-stick for the tool, it has negligible impact on the heat of the part.

|

|

|

|

Yeah it's just carbon of some flavour, and yes it's for lube.

|

|

|

|

How much should you tighten up an NT30 drawbar? I read snug tight but thats very subjective.

|

|

|

|

echomadman posted:Its probaby charcoal or some coal dust to act as an anti-stick for the tool, it has negligible impact on the heat of the part. Slung Blade posted:Yeah it's just carbon of some flavour, and yes it's for lube. Oh, okay. Thank you both!

|

|

|

|

Bit of a convoluted project idea, bear with me. Today I was helping my 8-year-old nephew chop some sticks for the fire-bowl-thingy, and he's outgrown baby's first hatchet and the tomahawk that was handy and the right length for him to swing two-handed and I one-handed had a bit of a short edge, and IMO too long a ... handle-to-blade distance for my liking. So that go me to thinking. I'd like a little one-handed axe. And bearded axes have always appealed to me, aesthetically. Something like this or this would be nice. But they're kinda expensive -- that Husky is the cheapest one I could find, and the sky's the limit. So I thought maybe I could make my own, but I don't have a smithy or the skills to truly make one from scratch. Then I remembered that rigger's axes exist. Contrary to what you may expect/have been told, that's a framing hammer first, hatchet second. But I could take one of those and cut away the underside on a curve from the notch to the bottom of the eye, it might be a delightful little camp axe, sort of like this* but more to my tastes. Quick and dirty Photoshop mockup:  (The sharpened pointy-ish bit at the bottom is good for picking up logs without having to bend over and suchlike.) Put that on a ~20" handle, and it'd be a hell of a lil' pack axe/pruning tool, right? Any reason this idea is doomed to failure? (*the Trail Hawk under "similar items" is what we were using, it's a smaller version of the same concept.) Chillbro Baggins fucked around with this message at 05:20 on Nov 21, 2017 |

|

|

|

The only difficulty is making sure you don't get the steel hotter than probably 500 degrees so you don't ruin the hardening/temper

|

|

|

Anyone know what this thing is called? I assume top piece is meant for pins for workholding. The unique part is that the bottom is rounded and sits on a giant felt collar, and can be spun and tilted.

|

|

|

|

|

Jeweler or watchmaker's vise probably.

|

|

|

M_Gargantua posted:

It's an engraving, or ball, vice. https://www.grs.com/browse/workholding/vises-blocks/ You can see one in use on a Purdey here : https://www.youtube.com/watch?v=ZSKBPBTnmIM&t=160s

|

|

|

|

|

Yep, that's an engraver's ball. Same arrangement gets used for any fine metalworking where working angle/position is critical and needs infinite adjustability, and where the forces involved are small enough that the weight of the ball is all you need to keep the entire assembly in the base socket. Pitch bowls for chasing/repousse work the same way, just with soft pitch for conforming workholding instead of a vise:  (i sit my own pitchbowl in a combo leather/rubber socket i made, i find the commercial rubber bases don't work well at steep angles)

|

|

|

|

e: This is probably the wrong thread for it.

Platystemon fucked around with this message at 19:35 on Nov 23, 2017 |

|

|

|

I've got some bad news for you...

|

|

|

|

I have a Rong Fu 45 clone I'd like to CNC. I'd like to reinforce the column to add rigidity and was wondering is filling the areas where the ball screw won't be with epoxy granite a good idea? Any other good ways to reinforce it? Edit: Found a post on cnccookbook doing the same thing to a very similar mill - https://www.cnccookbook.com/epoxy-granite-cnc-machine-fill/ - I guess it is worth investigating. Mudfly fucked around with this message at 09:41 on Nov 27, 2017 |

|

|

|

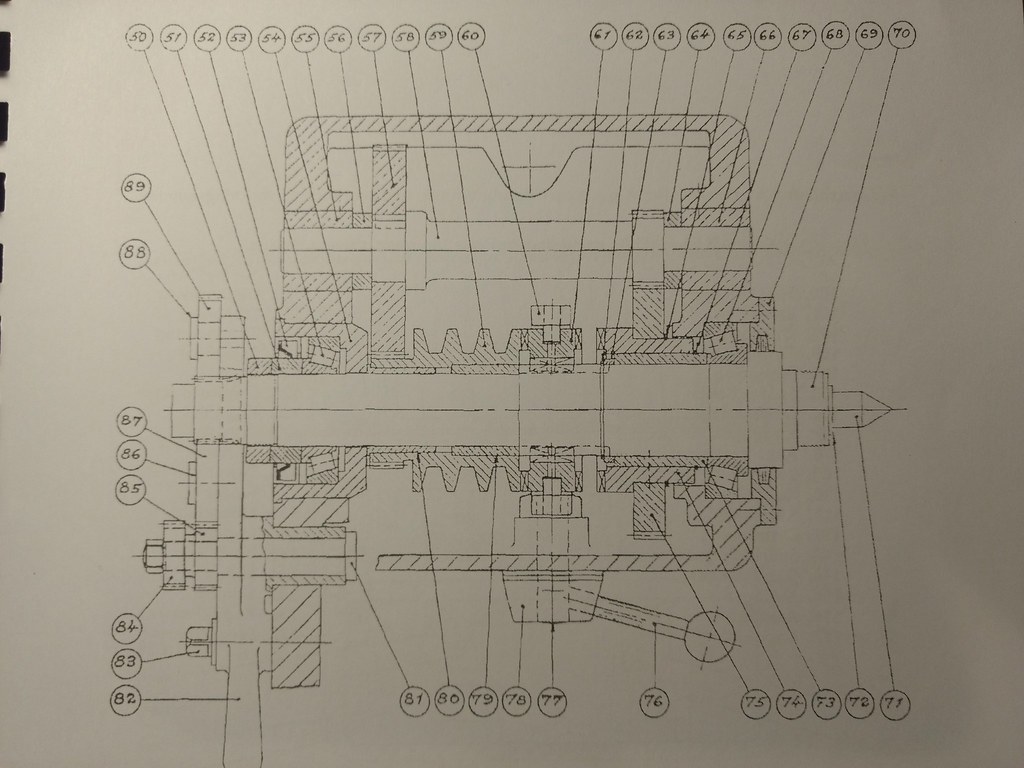

I've taken apart the headstock on my lathe, everything's getting a good cleaning and new grease: Secondary shaft + change wheels after ultrasonic dip  Spindle   Rear bearing in the bearing "cup":  Homemade puller to get the spindle out   Schematic of headstock:  Still a gearbox below to test and see if it needs some service. Also need to find out why the work lamp doesn't seem to function. A lot of this stuff is cleaned up by now but no pics of it.

|

|

|

|

Mudfly posted:I have a Rong Fu 45 clone I'd like to CNC. I'd like to reinforce the column to add rigidity and was wondering is filling the areas where the ball screw won't be with epoxy granite a good idea? Any other good ways to reinforce it? Have you checked the squareness of the ways and error over travel? I had a similar machine I was planning the CNC (created a 3d model found here: http://www.zincland.com/md001mill/). I gave up after I measured the error in the table and found 0.014" difference across the X travel and the X and Y axis was significantly out of square. It is possible to correct, but the amount of effort is substantial as you need to re-scrape the saddle and gibs. Also, after creating the model and running FEA on the column, I found the same issue you are trying to correct. The column on these machines is the biggest weak point in terms of stiffness. Adding the epoxy granite would help with damping even if it didn't add significant stiffness.

|

|

|

|

With these smaller mills, isn't the weakest (least rigid) link going to be the endmill anyway? i.e. the tool will deflect before the machine does?

|

|

|

|

|

| # ? May 24, 2024 01:50 |

|

ZincBoy posted:Have you checked the squareness of the ways and error over travel? I had a similar machine I was planning the CNC (created a 3d model found here: http://www.zincland.com/md001mill/). I gave up after I measured the error in the table and found 0.014" difference across the X travel and the X and Y axis was significantly out of square. It is possible to correct, but the amount of effort is substantial as you need to re-scrape the saddle and gibs. The flatness is about 2 thou out across the x, and 1 thou on the y. I haven't checked for parallelism. I do have a scraping table available though and a kind person who's offered to help me scrape it. Thanks for the model. The column stiffness now I think about it might be better improved by something else, perhaps another structure bolted to the back of the column. I wonder what stiffness considerations you'd have to make, and whether making it too stiff could introduce vibration problems. edit: I doubt it, actually - a big weldment spooning the column might be just the thing. Mudfly fucked around with this message at 09:54 on Nov 28, 2017 |

|

|

Bad Angus! Bad!

Bad Angus! Bad!