|

If you're really worried about table saw safety a table saw sled can really help. Verious jigs are nice too. Despite being useful as is, you can add some blade guards and rails so your hands have to really intentionally go near the blade. It helps. It's very nice for smaller cuts. Sadly for large cuts that don't fit the sled you're on your own! Just be mindful of the blade always. Here is the video I used to make mine: http://www.youtube.com/watch?v=69t6MFCUobw

|

|

|

|

|

| # ¿ Apr 29, 2024 16:15 |

|

I'm looking for a good beginner lathe and I was wondering if anyone had any suggestions. Since it's my first one I imagine I should just get something cheap, but the price ranges are just so crazy out there. What should I be looking for if I just want to turn some bowls and maybe try my hand at some custom chess pieces? Appreciate the help!

|

|

|

|

I don't know anything about lathes so I've been hesitant to look on craigslist or similar sites and have been just looking for new ones. Unfortunately the price is a bit prohibitive to get a decent one for $700. So lathe goons, is this a decent deal? I was thinking of offering $150 and working from there. http://toronto.en.craigslist.ca/tor/tls/3053779227.html Assuming it works. If it matters my main interest is turning bowl and anything smaller than that. Edit: Found another http://toronto.kijiji.ca/c-buy-and-sell-tools-power-tools-Ryobi-Wood-Lathe-37-plus-chisels-W0QQAdIdZ384590811 I apologize if these kind of posts aren't ideal, I just don't know where else to turn as a beginner. Help is much appreciated. keep it down up there! fucked around with this message at 21:16 on Jun 11, 2012 |

|

|

|

The Spookmaster posted:Advice Thanks so much for the advice. It helps a lot!

|

|

|

|

I hate to be that guy again, but I messaged a guy about this craiglist ad for a lathe and he agreed to $80. http://hamilton.en.craigslist.ca/bar/3111237024.html  Is this a good deal? I'm looking to do mainly bowl turning. I wish I knew more about this kind of thing or where to research it better.  Help is much appreciated.

|

|

|

|

Man thanks so much for all that info. That is exactly what I needed! I am in Burlington, which is between Hamilton and Toronto. $300 is about my budget as well. So thats perfect. I'll message the guy about the Hausman and see if he'll go lower. Thanks a ton! (You have an email I could shoot questions at if this falls through? I dont have PMs and I hate the idea of clogging this thread with craigslist ads.  ) )Edit: I contacted the guy offering $300 for the Hausman lathe. He said he stands firm at $400 as "It is in absolutely beautiful condition and has precise digital variable speed control.". If there are chucks with it is this still a good deal? Here is a pic he sent me:

keep it down up there! fucked around with this message at 21:13 on Jul 20, 2012 |

|

|

|

Guitarchitect posted:you should consider joining the Canadian Woodworking Forums. They're a bunch of old codgers but they know their stuff when it comes to older tools, and a few have even ruckered things for me (like I found a deal on a sander in Barrie and a dude from london happens to be going there for a weekend so he's picking it up for me and dropping it off in downtown TO since i don't have a car). They're really keen on old stuff and can often give you an idea of what your used deal will cost in order to bring it back up to working condition. Thanks, I will check them out! I didn't know this site existed. Not an Anthem posted:Edit- poo poo nevermind. That Haussmann gets bad reviews on Lumberjocks, and to boot the price people list buying in new or on sale is 250$ Thanks. I'll bail on it then. Appreciate the advice. I'll shoot you an email if I see another decent deal and I have any questions.

|

|

|

|

I made some wooden utensils out of a single piece of 3x3 maple.  Some more images here: http://imgur.com/gallery/m9tQv I based it on this instructable I found. Each piece probably took around 30 minutes, maybe a bit more. So much sanding, even with a quality dust mask and the garage door wide open it was a bit much. If I make more I might need to invest in some dust collection thats a bit more powerful than my shopvac.

|

|

|

|

Picked up a Rigid r4511 for $350 CAN yesterday. Wondering if I got a good deal. It came with about 10 blades as well, used but seem sharp and well cared for. The granite countertop seems like an insane feature. I had no idea the thing would be so heavy when I went to pick it up (452 lbs). But man it sure does look nice. I imagine stock slides like a dream on it. Haven't had a chance to use it yet, I need to replace the power cord. I somehow ripped it out at the button end transporting the heavy beast. Was definitely more than a 2 person job moving this thing. In retrospect I should have taken it completely apart, but I only had the truck rented for 90 minutes. I googled it and seems there was a recall in 2009 because of issues using a dado stack. Not sure if this was repaired or not, but I might call them and see if the repairs are still available. keep it down up there! fucked around with this message at 19:14 on May 29, 2014 |

|

|

|

The castors are pretty nice. The peddle you see raises and lowers them, so you can convert to proper legs for stability if need be.

|

|

|

|

Tim Thomas posted:This saw had an absolutely horrific failure mode if it was one of the recalled ones, so the first thing you should do is run, not walk, to the phone and call Ridgid to see if it was affected. We're talking "spinning dado blades detaching from arbor at speed and flying at user" horrific. I forget whether that was the case for single blades, but I'm a big fan of not having a real life version of Unreal's Ripper pointed at me in my shop. I found the recall notice and it only mentions dado blades, but I plan to call them anyways to be safe. https://www.ridgid.com/Media/Default/documents/safetynotices/R4511_PR.pdf The original owner passed away so I don't have any info on when it was bought or if it was repaired. Hopefully it won't be a huge hassle. Edit: Looks like I'm in the clear. "The recalled saws have manufacturing date codes between CD0829 and CD0837." Mine is CD0948 13118. Phew! I can't imagine I'll be getting a dado stack anytime soon anyways. I'll probably go the cheap route if I ever need one and just make a bunch of cuts with a single blade. At least until I start on a project that needs a lot. keep it down up there! fucked around with this message at 18:26 on May 30, 2014 |

|

|

|

wormil posted:You should also check to see if it has the alignment problem that has plagued Ridgid saws, I believe they finally have a replacement part to fix it. Ah thanks, I will check into that. I'm a newbie that knows nothing about this. I'm used to low end master craft stuff, but now that I finally have a garage Im trying to make a proper shop.

|

|

|

|

Stultus Maximus posted:Someone correct me if I'm wrong but I think the MasterForce, Ridgid, and Craftsman are all the same table saw. Mastercraft is a cheap Canadian Tire brand. I have a few of their tools I got from my parents and they are all really low quality. The table saw is frequently on sale for $100, and its rickety as all hell. I do not recommend them. http://www.canadiantire.ca/en/pdp/mastercraft-15a-table-saw-0556755p.html#.U4jjuvldWSo Though the belt sander I have from them is great, but I guess its hard to screw that up.

|

|

|

|

Blistex posted:Mastercraft is really hit or miss. Their planers (10+12") are pretty garbage, and their large hammer drills burn out really fast. Their scroll saws are pretty uninspired, as are their sanders (the orbital ones don't rune true and apply more pressure at the corners), and their biscuit joiners are literally the worst I have ever used (that also includes King). The only power tool they have made that actually impresses me is the Mastercraft 12A Plunge Router with Digital Display. It has all the different fittings and slots for using the Porter Cable guide rings, and a host of other base attachments. Also it takes both 1/2 and 1/4" bits. It's probably the only router under $200 that does all of that. I have a ton of their tools and you are right, most are poo poo. I keep asking for tools for Christmas from my parents because I just never need much else. They usually go the Mastercraft route so I've gathered a collection. The jointer might be the worst of them. I just can't get the 2 sides even no matter what I do so its impossible to make a clean cut. Complete waste of money. The table saw i had worked fine, but it's just weak and the fence is garbage. I was making a thick butchers block from hard maple and it struggled to make the cuts on the thick hard stock. The fence is too flexible so making a straight cut was also hard. I ended up using a sled for everything. If you just need rough work though they certainly get the job done cheaply.

|

|

|

|

Had my first experience with major kickback recently. I was cutting a 2x2x2 block and sent it smashing into the wall. Scary poo poo! Luckily I was off to the side, so only damage was a dent in the drywall. Funny enough it landed in my garbage can. I need to make my sleds new runners for my new table saw. Been lazy there and I shouldn't have been. Lesson learned!

|

|

|

|

I use a respirator anytime I am sanding, but not usually when just making cuts on the table or band saw. I should more often though. I work with my garage door open and have a fan that blows from the back outside. I'm torn on how much this helps vs kicking up more dust, but with the summer heat I kind of need it on regardless. =/ I also just use a shop vac, but I really think I need something more geared for dust collection. The shop vac works fine for cleanup, but doesn't seem as great for hooking to tools. Any suggestions there? The cheaper the better. I've debated trying to make something like matthias, but it might be a bit over my head.

|

|

|

|

I gotta agree. I got a really cheap Ryobi bandsaw and it's really noticeable that it lacks power. I have to cut any hard wood at an agonizingly slow pace or it just jams. I've tried everything and it's just bad. Glad I only paid $50 off kijiji for the thing.

|

|

|

|

If you aren't in a rush it might be worth waiting till the end of Nov for some sick Black Friday sales.

|

|

|

|

Work benches are one of those things I constantly want to remake. I'll make a new one for the garage and then a week later have ideas for a new one. I really should just settle in and make a Roubu style bench some day...

|

|

|

|

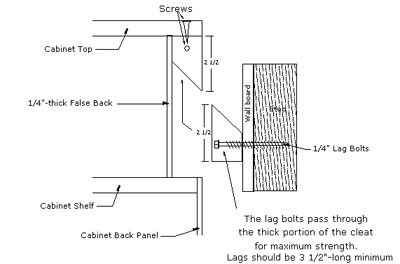

He is using the french cleat system, so rather than rest on the top there is a angled groove the items mount in. Here is a diagram

|

|

|

|

Matthias has rebuilt a few of his machines over time, so it's possible warping is some of the reason. He usually takes it as an opportunity to make a bigger version or add more features as well. So it's hard to tell. I bought the plans for his box joint jig, but I've been slacking on completing it and now it's gotten super cold in the shop. I should insulate my garage door and get a space heater really. I bought his band saw plans as well becayse my band saw is utter poo poo, but that's just proven to be a bit above my skill level for now, so it's also been shelved. Mostly it's issues with getting everything true and balanced. One day I'll finish a project... one day...

|

|

|

|

He did partner with a japanese guy to sell a metal version. You can buy it here: http://woodgears.ca/pantorouter/kuldeep/buy.html He does use it in a few videos, but I mostly see him use his home made one. He seems to use all his wood machines, but hes also clever enough and has the work ethic to repair/remake them if need be.

|

|

|

|

I'm also super jealous of that band saw. Picking up good used tools seems to be impossible in my area. Everything is either crazy overpriced or just cheap garbage  I've been trying for ages to find a decent lathe and band saw on craigslist and kijiji. I've been trying for ages to find a decent lathe and band saw on craigslist and kijiji.I'm currently using a terrible Ryobi bandsaw that just has no power and can't keep tension worth a drat. I really need an upgrade... Also super jealous of that Grripper deal. Here in Canada it's only sold at specialty stores for insane prices. Like $85. I should probably just order one from the US next time I see a sale. Probably cheaper in the end even with the higher shipping.

|

|

|

|

I was going to post this video as well. I used this method with a honing guide and even if I didn't get it absolutely perfect the change was extremely noticeable. Even the cheap chisels I own felt better than they did brand new. It works well on planes too. I managed to take a small nick out of my blade when I hit an errant staple I didn't see in the wood, and this method repaired it well. (though it took like an hour of solid scraping, ugh)

|

|

|

|

Cobalt60 posted:Is that your first Grr-ripper? I hate to throw the word life-changing about, but... I also got my first Grr-ripper. I am excited to put it to use! Anyone seen any good boxing week deals on planers? This seems to be the best I can find. DEWALT DW735 13-Inch, Two Speed Thickness Planer - Price: CDN$ 523.99 No idea why it says it's over a grand normally. Seems to be $699 most places when not on sale. Very weird. Anything better? Anyone experience with this planer? I've seen some cheaper ones around for as low as 350 but they all seem to have issues with snipe according to reviews. I've never used one before though so I'm just not sure how much to read into that. I should add I'm in Canada so we got retarded high prices for no reason.

|

|

|

|

Thanks for the planer help on the last page. I ended up ordering the DEWALT DW735 Thickness Planer. Dewalt even had a further $25 off at checkout that wasn't listed. So I scored it for under $500. Which about $200 off from the local retail price. Now I need people to convince me not to put end grain through it. I've read the horror stories, but god it's gonna be tempting when making cutting boards. keep it down up there! fucked around with this message at 19:31 on Dec 29, 2014 |

|

|

|

Bad Munki posted:I've done it. But I wouldn't recommend it. A far better approach would be a thickness sander. Sadly I don't think I can convince the wife on that kinda purchase for a while. Not after dropping $500 on the planer. I guess i'm sticking with the belt sander for a while. Maybe I'll try and make my own one day. Stumpy Nubs doesn't make it look too hard. After I finish some of the Matthias plans I've bought and haven't done anything with... Alternatively I should make some sort of router sled system. Nick Offerman has a massive one that makes me wish I had a bigger shop. keep it down up there! fucked around with this message at 16:24 on Dec 30, 2014 |

|

|

|

So you can glue right on the melamine and it won't stick? That's convenient. I guess it makes sense since it isn't wood, but it never occurred to me. I've been relying on my pipe clamp bars for the most part. I do put a piece of wood above and below with clamps to prevent bowing, but I always seem to get 1 or 2 peices out of alignment and then I gotta sand/hand plane like crazy. I'll try a melamine sandwich next time. I do have a lot of it leftover from some closet shelves we put in.

|

|

|

|

Well I'd had my new planer for about 10 minutes before I created a complete and total disaster. The wife told me it had come during the day. Arrived a week earlier than the shipping order said. So I was excited to get home and try it out. I get home, set it up. Everything is going smooth. Decide to try it out on some hard maple I had lying around. Turns out using a power planer without some kind of dust/chip collection is an absolutely terrible idea. The blower was pointed right at the bulk of my shop. Which now looks like a wood and dust grenade went off. Every single thing is just coated in chips. Oops! Works great though, thanks again for the suggestions  Time to make a million cutting boards. Time to make a million cutting boards.

|

|

|

|

Yeah I was too excited to try it out and wasn't thinking

|

|

|

|

French cleats are my plan as well when I finally get around to organizing my shop. Im just having a hard time settling on a layout for everything while managing all the junk in there. The junk has no home till I organize the shop which can't be organized easily with all the junk which has no home till I organize the shop... repeat till spring when I can dump everything on my driveway for a day and get it all sorted.

|

|

|

|

Tad late to the table saw safety posts, but anyways. I need to get a riving knife for my new saw(bought it used) and really have put it off far too long. I'm pretty careful as is (use a microjig and sled whenever possible), but really shouldn't be a good excuse not to have one. Any recommendations for one? I have a Rigid r4511 saw if that matters. How are the MicroJig splitters comparatively? The saw did come with the blade guard, like the one below. Does anyone here actually use these? They seem like a major hassle and in the way for anything but cutting large sheets. I use a table saw sled for 95% of my cuts and removing it and putting it back on seems like way too much work. Maybe I should be doing it though...

keep it down up there! fucked around with this message at 15:31 on Mar 23, 2015 |

|

|

|

Decided to bang out several end grain cutting boards last night. In the interest of efficiency I figured I'd cut it all at once. So I cut some big boards of paduk and purple heart into strips. All is well. Then I cut the same amount out of some nice hard maple I had so I could do alternating colour strips. All seemed well. Lined up all my alternating pieces and poured a ton of glue on em. Rolled it all out so it was all even. Then I started rotating the pieces so it was end grain up and I could clamp em together. About now is when I realized all the maple slices were considerably taller than the rest... I checked my sled and somehow my stop block got knocked over a good cm between boards. So every cutting board now currently looks like this: ■▮■▮■▮■▮■▮■▮■▮■ I probably shoulda just wiped off the glue and cut the pieces again, but I was so defeated I just clamped it up and left the shop. So now I have a ton of belt sanding/hand planing to do this weekend.

|

|

|

|

Squibbles posted:Maybe use a router flattening jig. That should be reasonably quick about taking off those high points. Assuming you have a router that is. Thats a good idea. I DO have a router! I'll just need to get a flat bit. Shame tomorrow is a holiday.

|

|

|

|

The only router bits I own are roundover bits. I guess I'll head to Lee Valley tomorrow and grab a bowl, straight, and spiral bit! Thanks!

|

|

|

|

Bottom cleaning bit worked out great. Thanks for the advice. Before  Jig  After  Tonight I'll cut them square and give am a final sanding to get em smooth.

|

|

|

|

His Divine Shadow posted:Joke option: Build the smaller style DC but put the 4kw motor and oversized impeller on it.... Hmmmm.... Go with the joke option. More power!

|

|

|

|

Table saw jigs are a good alternative as well. Steve Ramsay makes one in this video. https://www.youtube.com/watch?v=vrYjc3G1vgo

|

|

|

|

Not exactly a woodworking question, but here goes. I'm in a mens slowpitch softball league and we have to provide our own home plate (a 2 foot x 3 foot plywood board). To jazz things up I decided to get our logo printed on vinyl to give us a nice fancy plate (and crush our enemies spirits who just have plain plywood plates). I'm wondering the best way to apply it and make sure it stays strong. The plate will have softballs dropping on it all game long, so it needs to stand up to that abuse. Runners don't run on the plate so there is no cleat risk, but the balls will still be hitting decently hard. The vinyl is a big sticker. I figure I need to add a strong clear coat overtop both it and the board. What would be the bext product to use? I was thinking epoxy, but that seems expensive. A guy on reddit suggested spar urethane but the board is painted white, would that still work? The container says to use on wood without paint or finish.

|

|

|

|

|

| # ¿ Apr 29, 2024 16:15 |

|

Nice find. I just inherited some Delta tools and its so nice to have actual high quality items now. A jointer is still on my list. On the lookout for a lathe too and then my "big tool" needs are complete (haha yeah right). Maybe he will mail it to you! Worth a shot. Could offer to paypal the mail fees.

|

|

|